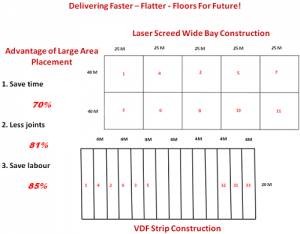

LTFS is a name that has become synonymous with quality flooring solutions. We bring in state of the art machinery S 15 R laser screed machine with telescopic boom for the purpose of laying the floors Vs Conventional VDF Flooring.

Also, we prefer Steel fibre reinforced concrete as an alternate to traditional mesh reinforcement. Glued Steel Fibre Reinforced Concrete (SFRC)-provides you with a time saving and cost efficient solution for flooring. Being Multi dimensional reinforcement it offers following advantages:-

- Optimal Load bearing

- Optimal Crack control

- High fatigue resistance

- High impact resistance

Get more out of your slab

- Easier to maintain

- Longer lifespan

- Optimized Thickness

- Timesaving construction

- Better Performance

- The ductile steel fibre floor with stands moderate deformations, minimizes curling of concrete slab.

- Easier and more accurate installation of Super flat floor.

Steel fibres are commonly used in concrete to provide structural (load-bearing) capacity and for the control of shrinkage-induced cracking. Steel fibres for reinforcing concrete are manufactured from cold-drawn wire and are used in grade or ground supported floors. Normally the preferred length is 60 mm, with aspect ratios of 80 (ratio of length to nominal diameter). In order to gain pull-out resistance fibres have hooked end profile.

Use of Steel Fibres in industrial and warehouse flooring reduces energy consumption by 16% (Approx.) per SQM in comparison with steel bar / mesh reinforcement. Also, Steel Fibres act as environment friendly concrete reinforcement designed to offer an easy to use alternative for traditional steel mesh and bar reinforcement. Depending on the finished product type, different top wire rod sources are applied. On the overall Steel Fibre Production volume, manufactures can state the percentage of recycled steel used in their end product which may be around 20%.

Lamba Techno Flooring Solutions Pvt Ltd brings to Local Markets, New Technology of Reactive Colloidal Silica Nano Technology from Lythic USA for Densification & Dust-proofing, creating “The HardWear FloorTM” for existing and newly trowelled green concrete floors. Until recently, all densifiers used alkali-metal compounds called “silicates” – such as sodium silicate, potassium silicate, or lithium silicate. Silicates are old technology. They have many drawbacks, which are overcome by a new type of densifier chemistry, colloidal silica Nano Technology.

LYTHIC Colloidal Silica Nano Technology: New Technology for Better Concrete –

Reactive Colloidal Silica – nano-sized particles in an acqueous suspension – are the heart of Lythic advanced concrete treatment system. Reactive Colloidal Silica is 99.5% pure silica suspended in an ultra-low surface tension liquid. The nanometer particles in their low-viscosity suspension penetrate quickly, deeply, and cleanly into concrete. Reactive Colloidal Silica also bonds to itself, a property not found in any silicate densifier. They react very efficiently with lime in concrete, making them far more reactive than conventional silicate densifiers. These reactions form cementitious compounds in the concrete’s pores that harden and densify the surface.

- Creates a Hard, Durable Floor

- Low Cost and Easy to Maintain

- “Green” Flooring

Lythic™ Densifier is a blend of inorganic polymer materials that penetrates slab concrete to increase surface density and hardness. Utilizing a proprietary and “green” manufacturing process, Lythic™ Densifier’s unique formulation of uniform, concentrated, Nano sized particles, suspended in an ultra low surface tension liquid, penetrates deeply into concrete surfaces bonding with the cement components of the slab. Lythic™ Densifier makes an extremely hard, dense floor surface that has increased wear resistance to foot and fork lift traffic. It is water based and environmentally friendly and is VOC compliant in all states.

| Old Technology: Silicate-based Densifiers | New Technology: Lythic Colloidal Silica |

| Highly caustic with 11 pH or greater | 9 pH, a thousand times safer |

| High viscosity requires scrubbing to break surface tension, adding to labour cost | Low viscosity and simple spray-on application for quick penetration |

| Slow reacting, can require overnight dwell time | Reacts within minutes. Does not delay project |

| Alkaline residues require additional labour to remove and treatment as hazardous waste | No alkaline surface residue. No disposal costs |

| Surface must be rinsed to remove residue as water damage to building and finishes is possible | No rinsing required |

| Potential for difficult to remove surface whiting | No potential for whiting |

| Contains water soluble compounds that may be left in the slab and cause problems | Does NOT contribute to alkali-silica- reaction (ASR) which can cause swelling and cracking |

| Inconsistent and variable sized particles | Consistent 5 nanometer -sized particles |

With experience of laying more than 1 Million M2 of floor in last 4 years, we are here to deliver floors as per International standards. So when plan your next project you think of us as reliable business partner and not just another vendor.

… Delivering Faster – Flatter – Floors for Future!